Reverse engineering

Why reverse engineering?

Why reverse engineering?

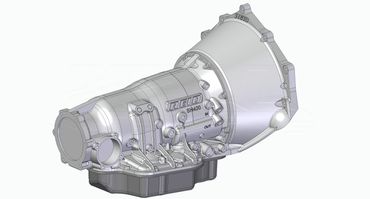

In many of today's fast paced industries designers are creating first articles by hand in metal, clay, foam rubber, wood and many other forms, often these are organic in shape and difficult to model in a computer. This is where reverse engineering, in the form of laser scanning comes in. We can accurately scan and replicate almost any item in CAD using this process.

Below are just a few of the numerous reasons you may need an item reverse engineered.

- Original manufacturer is no longer in business or offering the part.

- You need a revision of an existing part with no existing data.

- OEM data is not available to serve as a base for your new product design.

- Historical preservation of custom, hand built components.

- Analyze the good and bad features of your competitors products.

- Lost or non existing data for a product.

- Comparison of finished goods to original CAD data model.

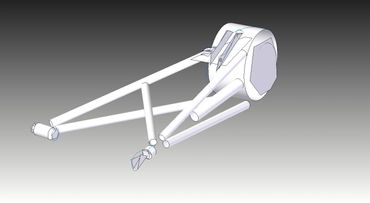

Vehicle frame scanning

Portable CMM/ laser scanning

Why reverse engineering?

Have a prototype chassis built by hand? We can assist in creating a model ready for production, including laser cutting and CNC bending. We have the experience in tube design and fabrication to best suit your manufacturing methods.

This is also a great way to preserve and document historical race vehicles that have no physical records.

Portable CMM/ laser scanning

Portable CMM/ laser scanning

Portable CMM/ laser scanning

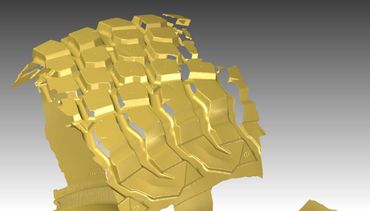

Utilizing the latest hardware and software available, we're able to assist you in getting your product into a CAD format you need.

Using our Romer CMM arm with integrated laser scanner or Creaform white light scanner we can capture data from almost any objects surface and create a working CAD file.

We can scan items in our office or yours as we are fully mobile to any location.